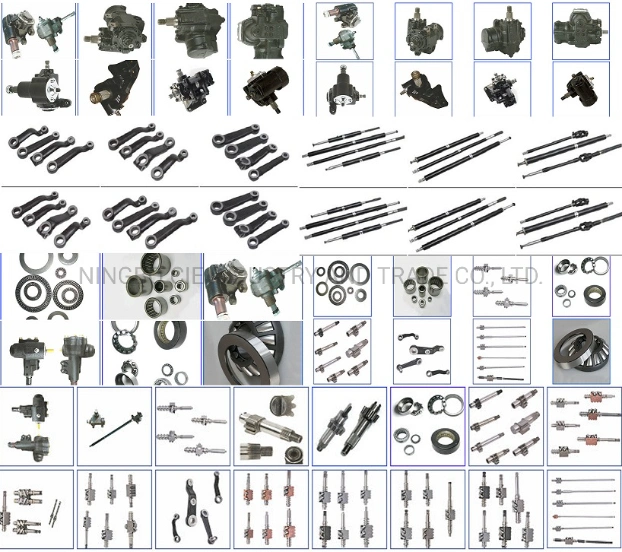

Steering Column & Worm Shaft Assembly for Ford

Steering Column & Worm Shaft Assembly For FORD The static properties of the screw and nut assembly itself are determined

Basic Info.

| Model NO. | FR1 |

| Standard | Standard |

| Condition | New |

| Transport Package | in Craft Paper Carton |

| Specification | ISO9002 |

| Trademark | CIE |

| Origin | Ningbo, Zhejiang, China |

| HS Code | 87089440 |

| Production Capacity | 50, 000PCS/Month |

Product Description

Steering Column & Worm Shaft Assembly For FORDThe static properties of the screw and nut assembly itself are determined by multiple, often conflicting factors: Minimal flank backlash between the nut and screw means optimum reproducibility but at the same time places increased demands on the screw thread geometry. A higher bearing percentage on the screw flanks improves axial load-bearing capacity and service life on the one hand, but is reflected on the other hand by greater sensitivity of the screw-nut system to production tolerances.

And it is the correct and accurate operation of the transmission system which is usually decisive in determining the quality of the end product, which is why the production of a screw and nut assembly is something best left to the experts

The production of nuts for your screw and nut assembly poses equally stringent quality requirements. Our own toolbuilding shop is evidence of our flexibility and commitment in the service of our customers - lead screw taps even in special forms are no obstacle, at least not for us. Complicated forms on screws or nuts in conjunction with a high accuracy requirement present as little of a problem as galvanization

The ball screw assembly steering gears consists of a screw and a nut, each with matching helical grooves, and balls which roll between these grooves between the nut and the screw when the nut or screw is rotating. The balls are deflected by the deflector into the ball return system of the nut and they travel through the return system to the opposite end of the ball nut in a continuous path, and exit from the ball return system into the ball screw and nut thread raceways continuously to recirculate in a closed circuit.

The ball nut assembly: Ball nut determines the load and life of the ball screw assembly.

The ratio of the number of threads in the ball nut circuit to the number Of threads on the ball screw determines how much sooner the ball nut will reach Fatigue failure (wear out) than the ball screw will. Ball nuts are manufactured With two types of return systems.

We can produce it according to your drawing,even with old samples! mainly for racing teams

Other Relative series:

We attend some professional fair and abroad.

Send to us